Non-Explosive Demolition Agent

For 25 years, engineers, plant maintenance personnel and drilling and blasting contractors have relied on our assistance to make a wide variety of building demolition and controlled demolition projects manageable and successful.

Backed by Demolition Technologies' track record of success, Bustar delivers best-case non-explosive demolition outcomes that you can depend on.

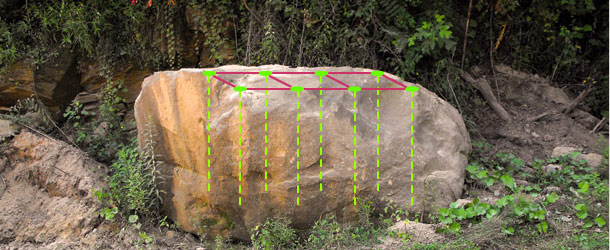

Controlled Rock & Concrete Demolition

Bustar expansive grout has been used in thousands of projects ranging from concrete removal and concrete demolition of structures ranging from small equipment pads to massive bridge piers, heavily reinforced turbine foundations and lock wall pre-splitting.

Our rock breaking chemicals are ideal for rock demolition ranging from boulders to massive granite lifts in the dimensional stone quarrying industry, rock trenching to site development in schist, sandstone, marble, granite, limestone, and quartz. If you are working in pulp and paper, power, heavy industrial, steel, site excavation, or trenching, we understand your application and bring real world expansive concrete demolition experience to it.

From concrete demolition to rock demolition, the Bustar non-explosive demolition agent is the predictable safe and silent demolition solution.

Ranging from turnkey removal to rock drill rental we can provide whatever level of assistance needed through Bluegrass, the nation's leading demolition contractor. Bluegrass supervisors, equipment, and skilled personnel will support your project as required. From diamond wire sawing to robotic hammering to complete demolition, we have what it takes.

Demolition Technologies provide straight answers based on real world experiences which take into account your specific project's parameters for choosing non-explosive demolition. These may include speed, silence, zero vibrations, no emissions, surrounding equipment, and confined space.

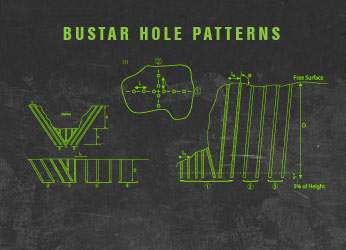

Our support means customized drill patterns, hole spacing and diameter, technical information including temperature ranges, safety measures and resources, consulting and engineering services, shipping and delivery options.

If you are working in pulp and paper, power, heavy industrial, steel, site excavation, or trenching, we understand your rock demolition application and give you a project proven expansive grout product that is backed by real world experience and delivers results.